Introduction

The global demand for PP woven fabric and bags has increased significantly due to the need for strong, lightweight, cost-effective, and sustainable packaging solutions. As a trusted PP woven fabric and bags manufacturer, we cater to industries that require reliable packaging for storage, transportation, and export of bulk materials.

Polypropylene (PP) woven fabric is manufactured by weaving flat polypropylene tapes into a strong and durable structure. This fabric is widely used to produce PP woven sacks, PP woven bags, PP sack bags, and PP woven big bags (jumbo bags/FIBC). These packaging solutions are known for their high tensile strength, moisture resistance, flexibility, and long service life.

Industries such as agriculture, cement, construction, food processing, fertilizers, chemicals, and industrial packaging heavily rely on PP woven bags because they offer superior performance compared to traditional packaging materials like paper, jute, and plastic films.

As a professional PP woven bag manufacturer, we focus on:

- Consistent product quality

- Custom manufacturing as per industry requirements

- Advanced production technology

- Domestic and export-grade packaging solutions

This comprehensive guide will help you understand:

- What PP woven fabric is and how it is manufactured

- Different types of PP woven sacks, bags, and big bags

- Applications across various industries

- Benefits of choosing PP woven packaging

- How to select the right PP woven fabric & bags manufacturer

Whether you are looking for PP woven fabric rolls, PP woven sack bags for agriculture, or heavy-duty PP woven big bags for bulk packaging, this pillar page provides everything you need to make an informed decision.

What Is PP Woven Fabric?

PP woven fabric, also known as polypropylene woven fabric, is a high-strength industrial material produced by weaving flat polypropylene tapes in a crisscross (warp and weft) pattern. This weaving process creates a fabric that is lightweight yet extremely durable, making it ideal for heavy-duty packaging applications.

As a leading PP woven fabric and bags manufacturer, we use premium-grade polypropylene granules to ensure consistent strength, flexibility, and long service life in every fabric roll and finished product.

Composition of PP Woven Fabric

PP woven fabric is made from 100% polypropylene, a thermoplastic polymer known for:

- High tensile strength

- Resistance to chemicals and moisture

- Lightweight structure

- Recyclability

The polypropylene granules are melted, extruded into thin flat tapes, stretched for strength, and then woven into fabric using circular or flat looms.

Structure of PP Woven Fabric

The woven structure of PP fabric provides superior load-bearing capacity compared to non-woven materials.

Key structural elements include:

- Warp tapes: Longitudinal threads that provide strength

- Weft tapes: Horizontal threads that offer stability

- Weaving pattern: Tight interlocking for enhanced durability

- Optional lamination: Poly coating for moisture and dust resistance

This structure makes PP woven fabric suitable for producing PP woven sacks, PP woven sack bags, PP woven bags, PP bags, and PP woven big bags.

Key Properties of PP Woven Fabric

PP woven fabric is widely preferred due to its excellent material properties:

- High tensile strength: Handles heavy loads without tearing

- Moisture resistance: Ideal for storage and transportation

- Chemical resistance: Suitable for fertilizers and chemicals

- Lightweight: Reduces logistics and transportation costs

- Customizable: Available in various GSM, widths, and colors

- UV resistance (optional): Extended outdoor life

- Recyclable & eco-friendly: Supports sustainable packaging

PP Woven Fabric vs Non-Woven Fabric

Understanding the difference helps buyers choose the right packaging material:

| Feature | PP Woven Fabric | PP Non-Woven Fabric |

|---|---|---|

| Strength | High | Medium |

| Load Capacity | Heavy-duty | Light-duty |

| Structure | Woven tapes | Bonded fibers |

| Durability | Long-lasting | Short-term |

| Usage | Sacks, bags, big bags | Shopping & promotional bags |

Due to its superior strength and durability, PP woven fabric is the preferred choice for industrial and bulk packaging applications.

Why PP Woven Fabric Is Widely Used in Packaging

The combination of strength, cost efficiency, and versatility makes PP woven fabric the backbone of modern industrial packaging. It forms the base material for:

- PP woven sack bags for agriculture

- PP woven bags for cement & construction

- PP woven big bags for bulk packaging

- PP woven fabric rolls for industrial use

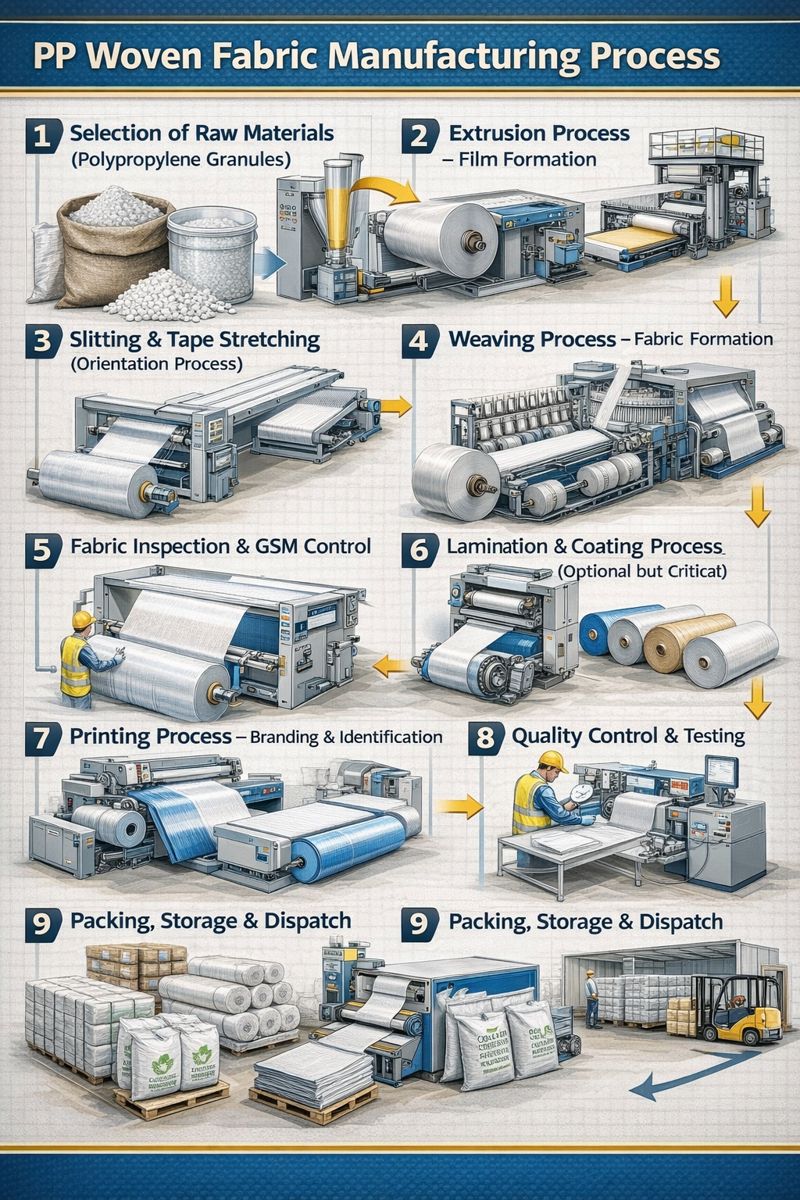

PP Woven Fabric Manufacturing Process

The manufacturing process of PP woven fabric and bags plays a critical role in determining the strength, durability, appearance, and performance of the final packaging product. As an experienced PP woven fabric and bags manufacturer, we follow a highly controlled and systematic production workflow to ensure that every PP woven sack, PP woven bag, PP sack bag, and PP woven big bag meets industrial and export-quality standards.

Below is a detailed step-by-step explanation of the PP woven manufacturing process used in modern packaging facilities.

1 Selection of Raw Materials (Polypropylene Granules)

The production process begins with the careful selection of polypropylene (PP) granules, which directly impact the mechanical properties of the woven fabric.

Types of raw materials used:

- Virgin polypropylene granules: preferred for food-grade and export packaging

- Reprocessed or recycled PP granules: used for cost-effective industrial applications

- UV stabilizers: improve resistance to sunlight degradation

- Antioxidants & additives: enhance durability and flexibility

- Color masterbatch: enables customized fabric colors

The ratio of virgin to recycled material is optimized based on application requirements, ensuring the right balance between strength, cost, and sustainability.

2 Extrusion Process – Film Formation

In this stage, polypropylene granules are fed into a high-temperature extrusion machine.

Process details:

- Granules are melted at controlled temperatures (around 240–260°C)

- The molten polymer is extruded through a flat die

- A thin polypropylene film is formed

- The film is rapidly cooled to maintain molecular stability

This step ensures uniform thickness and surface quality, which is essential for consistent PP woven fabric performance.

3 Slitting & Tape Stretching (Orientation Process)

The extruded PP film is slit into narrow tapes and then stretched to enhance strength.

Why stretching is important:

- Aligns polymer molecules

- Increases tensile strength

- Improves tear resistance

- Reduces elongation under load

Key outcomes:

- Strong flat PP tapes

- Uniform tape width

- Enhanced load-bearing capacity

These tapes are the backbone of PP woven sacks, PP woven bags, and PP woven big bags.

4 Weaving Process – Fabric Formation

The stretched tapes are woven using circular looms or flat looms.

Weaving specifications:

- Controlled warp and weft density

- Adjustable GSM (40–150+ GSM)

- Uniform fabric tension

- High production efficiency

The weaving process creates a tightly interlocked fabric structure that delivers:

- High tensile strength

- Excellent shape retention

- Long-term durability

This woven fabric is supplied as PP woven fabric rolls or processed further into finished bags.

5 Fabric Inspection & GSM Control

Before conversion, the woven fabric undergoes inspection to ensure:

- Consistent GSM

- Uniform weave pattern

- No broken or loose tapes

- Smooth surface finish

Strict GSM control is critical to meeting industry-specific packaging requirements.

6 Lamination & Coating Process (Optional but Critical)

For applications requiring moisture and contamination protection, the woven fabric is laminated.

Lamination methods:

- Extrusion lamination

- Heat lamination

Benefits of lamination:

- Moisture and dust resistance

- Enhanced printing quality

- Improved shelf life of packed materials

- Higher resistance to tearing

Laminated PP woven fabric is essential for cement bags, fertilizer sacks, food packaging, and chemical bags.

7 Printing Process – Branding & Identification

Printed PP woven bags improve product visibility and brand recognition.

Printing techniques used:

- Flexographic printing (cost-effective, fast)

- Rotogravure printing (high-resolution graphics)

Printing features:

- Up to 6+ color printing

- Logo, batch details & regulatory information

- Long-lasting ink adhesion

- Sharp image clarity

Custom printing transforms standard PP woven bags into powerful branding tools.

8 Bag Conversion – Cutting, Stitching & Assembly

The laminated or non-laminated fabric is converted into finished packaging products.

Conversion operations include:

- Precision cutting to size

- Bottom and side stitching

- Heat sealing options

- Gusseting for increased capacity

- Valve fitting (for cement & chemicals)

- Inner liners for moisture-sensitive products

For PP woven big bags (jumbo bags/FIBC):

- Loop attachment

- Reinforced seams

- Safety factor compliance (5:1 or 6:1)

9 Quality Control & Testing

Every batch undergoes strict quality control to ensure reliability.

Key quality tests:

- Tensile strength testing

- Seam strength testing

- Load and drop tests

- UV resistance testing

- Dimensional accuracy checks

- Visual inspection

This ensures that each PP woven sack, PP woven bag, and PP woven big bag meets domestic and export standards.

10 Packing, Storage & Dispatch

Finished products are:

- Baled or palletized

- Stored in controlled environments

- Dispatched as per customer and export requirements

Proper packing ensures damage-free delivery and consistent quality.

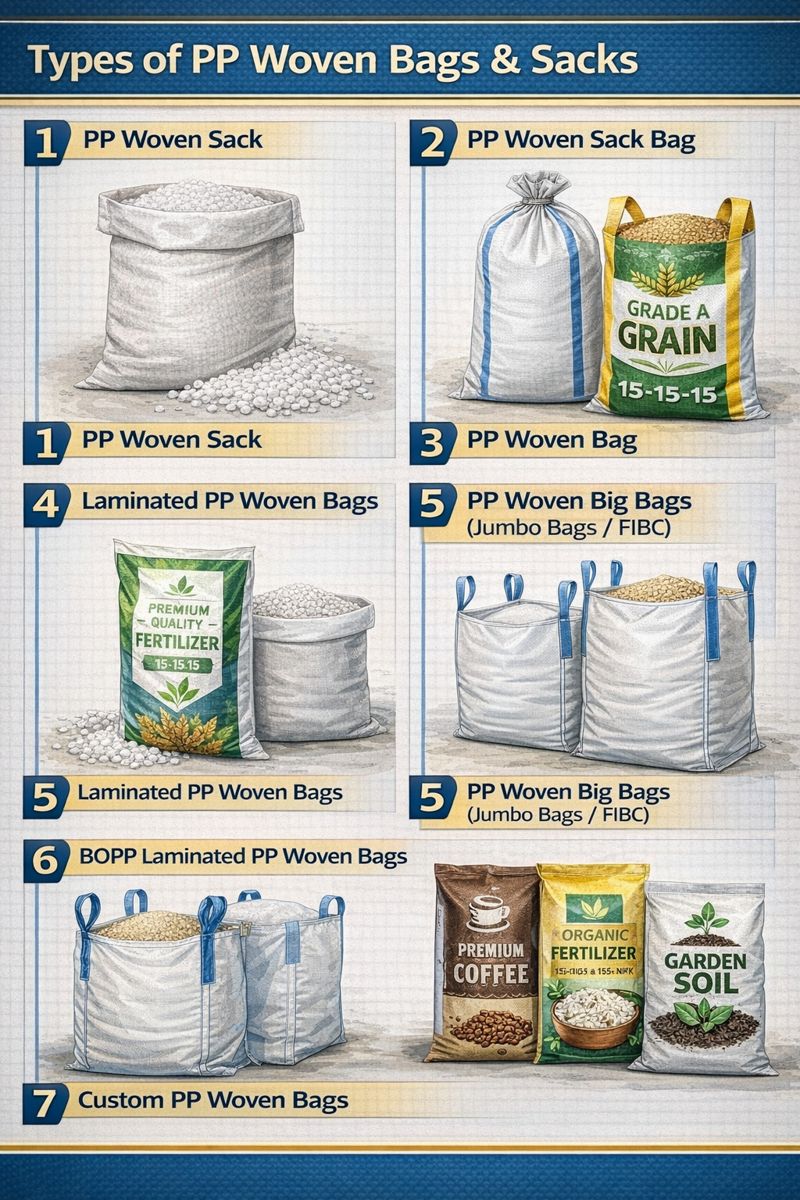

Types of PP Woven Bags & Sacks

PP woven packaging is available in multiple forms to meet the diverse needs of industrial, agricultural, and commercial sectors. As a professional PP woven fabric and bags manufacturer, we produce a wide range of PP woven sacks, PP woven sack bags, PP woven bags, PP bags, and PP woven big bags, each designed for specific load capacities and applications.

Below is a detailed classification of PP woven packaging types, including their features, benefits, and applications.

1 PP Woven Sack

PP woven sacks are the most commonly used packaging solution for bulk storage and transportation. They are manufactured using high-strength polypropylene woven fabric and are suitable for both domestic and export markets.

Key Features

- High tensile and tear strength

- Lightweight yet durable

- Available in laminated and non-laminated variants

- Optional inner liner for moisture protection

Benefits

- Cost-effective bulk packaging

- Excellent resistance to moisture and chemicals

- Easy handling, stacking, and transportation

- Long service life even under rough handling

Applications

- Cement and construction materials

- Fertilizers and chemicals

- Animal feed and seeds

- Industrial raw materials

2 PP Woven Sack Bag

PP woven sack bags are widely used in agriculture and food storage where product safety and durability are critical.

Key Features

- Custom sizes and capacities

- Strong stitching and reinforced seams

- Optional BOPP or PP lamination

- Food-grade material option

Benefits

- Protects contents from moisture and contamination

- Maintains product quality during long storage

- Custom printing for branding and product information

- Reusable and recyclable

Applications

- Grains, rice, wheat, maize

- Sugar and flour packaging

- Fertilizers and agro products

- Food and agricultural commodities

3 PP Woven Bag

PP woven bags are versatile packaging solutions suitable for medium-weight packaging and retail distribution.

Key Features

- Available with or without lamination

- Custom colors, printing, and GSM

- Gusseted and non-gusseted options

Benefits

- Attractive packaging with branding options

- Strong load-bearing capability

- Reduced packaging costs

- Environment-friendly alternative to plastic films

Applications

- Retail food packaging

- E-commerce and logistics

- Industrial packaging

- Promotional and branded packaging

4 Laminated PP Woven Bags

Laminated PP woven bags are coated with a polypropylene layer to enhance protection.

Key Features

- Moisture and dust resistance

- Improved print quality

- Smooth surface finish

Benefits

- Longer shelf life of packed goods

- Enhanced branding visibility

- Protection against humidity and contamination

Applications

- Cement bags

- Fertilizer packaging

- Chemical products

- Food-grade packaging

5 PP Woven Big Bags (Jumbo Bags / FIBC)

PP woven big bags, also known as jumbo bags or FIBC (Flexible Intermediate Bulk Containers), are designed for heavy-duty bulk handling.

Key Features

- Load capacity ranging from 500 kg to 2000 kg

- Single, double, or four lifting loops

- Safety factor 5:1 or 6:1

- Anti-static and conductive options

Benefits

- Efficient bulk transportation

- Reduced handling and logistics cost

- High safety and load stability

- Custom designs for specific industries

Applications

- Chemicals and minerals

- Construction materials

- Agricultural bulk storage

- Export and international shipping

6 BOPP Laminated PP Woven Bags

BOPP laminated PP woven bags are premium packaging solutions with high-quality printed film lamination.

Key Features

- High-resolution graphics

- Glossy or matte finish

- Superior tear resistance

Benefits

- Strong visual branding

- Increased product appeal on shelves

- Moisture-proof and durable

Applications

- Branded food packaging

- Fertilizers and seeds

- Retail and export packaging

7 Custom PP Woven Bags

Custom PP woven bags are manufactured according to specific customer requirements.

Customization Options

- Size and weight capacity

- GSM and fabric color

- Printing and branding

- Gussets, handles, liners, and valves

Benefits

- Perfect fit for product needs

- Brand differentiation

- Improved packaging efficiency

Applications

- Industry-specific packaging

- Private-label packaging

- Export-oriented products

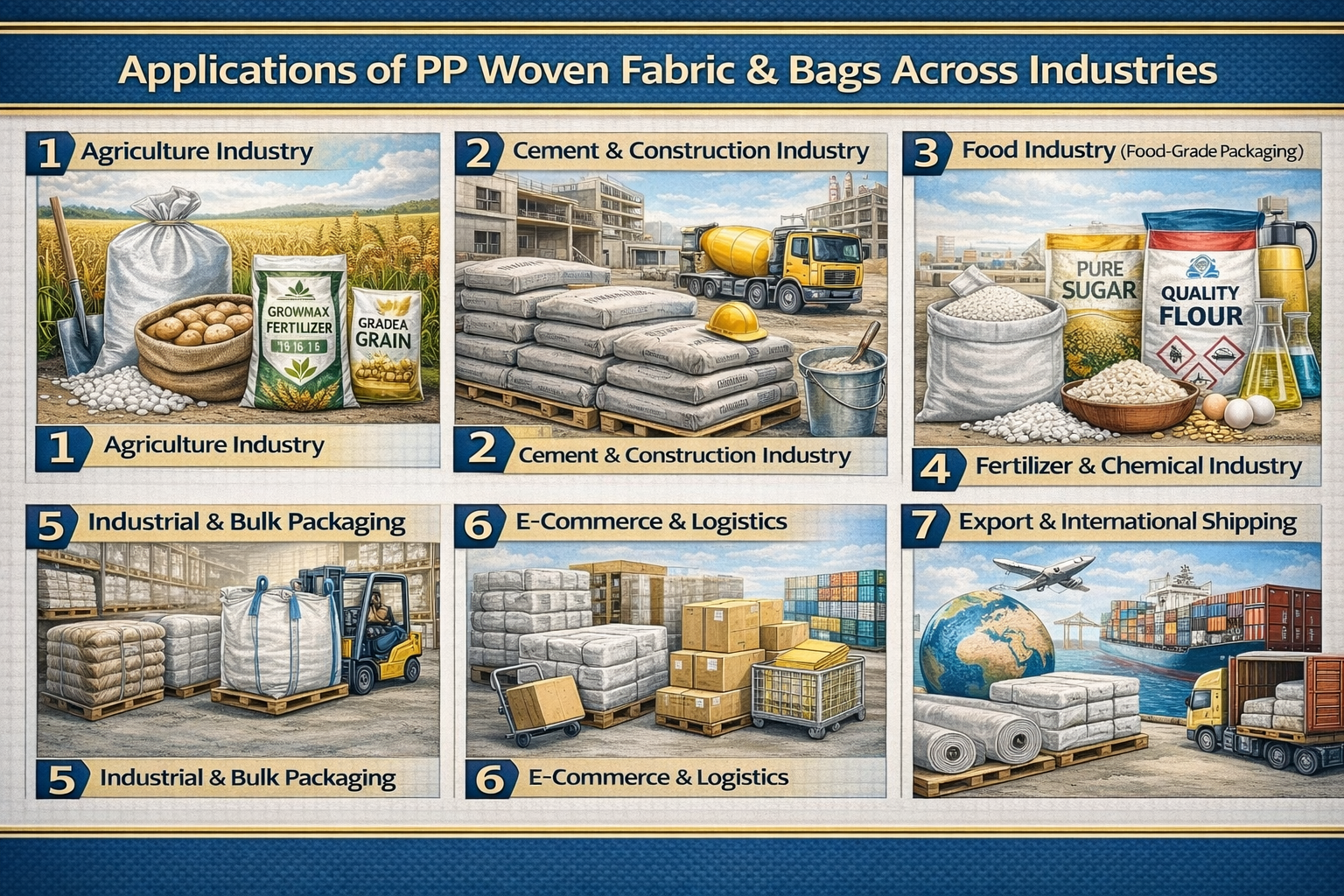

Applications of PP Woven Fabric & Bags Across Industries

The versatility, strength, and cost efficiency of PP woven fabric and bags make them a preferred packaging solution across multiple industries. As an experienced PP woven fabric and bags manufacturer, we supply customized PP woven packaging solutions that meet the specific handling, storage, and transportation needs of different sectors.

Below is an industry-wise breakdown of how PP woven sacks, PP woven sack bags, PP woven bags, PP bags, and PP woven big bags are used in real-world applications.

1 Agriculture Industry

The agriculture sector is one of the largest consumers of PP woven sack bags due to the need for durable and moisture-resistant packaging.

Applications

- Rice, wheat, maize, and grain storage

- Seeds and animal feed

- Fertilizers and pesticides

Why PP Woven Bags Are Preferred

- High strength for heavy loads

- Protection against moisture and pests

- Breathability (non-laminated options)

- Reusable and recyclable

Common Products Used: PP woven sack bags, laminated PP woven bags, BOPP laminated PP woven bags

2 Cement & Construction Industry

Cement and construction materials require heavy-duty packaging that can withstand rough handling.

Applications

- Cement packaging

- Sand and aggregates

- Construction chemicals

Benefits of PP Woven Packaging

- High tear and burst strength

- Moisture-proof lamination

- Valve and block bottom options

- Long shelf life in storage

Common Products Used: PP woven sacks, laminated PP woven bags, valve sacks

3 Food Industry (Food-Grade Packaging)

Food products demand hygienic, safe, and contamination-free packaging.

Applications

- Sugar, flour, salt, and grains

- Rice and pulses

- Animal feed and pet food

Why PP Woven Bags Are Ideal

- Food-grade PP material

- Optional inner liners

- Odor-free and non-toxic

- Custom printing for labeling

Common Products Used: Food-grade PP woven sack bags, laminated PP woven bags

4 Fertilizer & Chemical Industry

Fertilizers and chemicals require packaging that resists moisture and chemical reactions.

Applications

- Urea and phosphate fertilizers

- Industrial chemicals

- Specialty compounds

Advantages

- Chemical resistance

- Anti-slip and laminated options

- High load capacity

- Custom safety markings

Common Products Used: PP woven sacks, laminated PP woven bags, PP woven big bags

5 Industrial & Bulk Packaging

Industries handling bulk materials require robust packaging for storage and transport.

Applications

- Industrial raw materials

- Minerals and powders

- Plastic granules

Benefits

- High stacking strength

- Reduced packaging loss

- Cost-effective bulk handling

**Common Products Used: **PP woven bags, PP woven big bags (jumbo bags/FIBC)

6 E-Commerce & Logistics

PP woven bags are increasingly used in logistics due to durability and reusability.

Applications

- Bulk transport packaging

- Warehouse storage

- Export shipments

Why PP Woven Bags Work

- Lightweight for reduced shipping cost

- Tear resistance during handling

- Reusable for multiple cycles

Common Products Used: PP woven bags, PP woven sack bags

7 Export & International Shipping

Export packaging requires compliance with international standards.

Applications

- Bulk exports

- Containerized shipments

- Cross-border logistics

Export-Specific Benefits

- Compliance with international packaging norms

- UV-stabilized fabric for outdoor storage

- High safety factor big bags

Common Products Used: PP woven big bags (FIBC), heavy-duty PP woven sacks

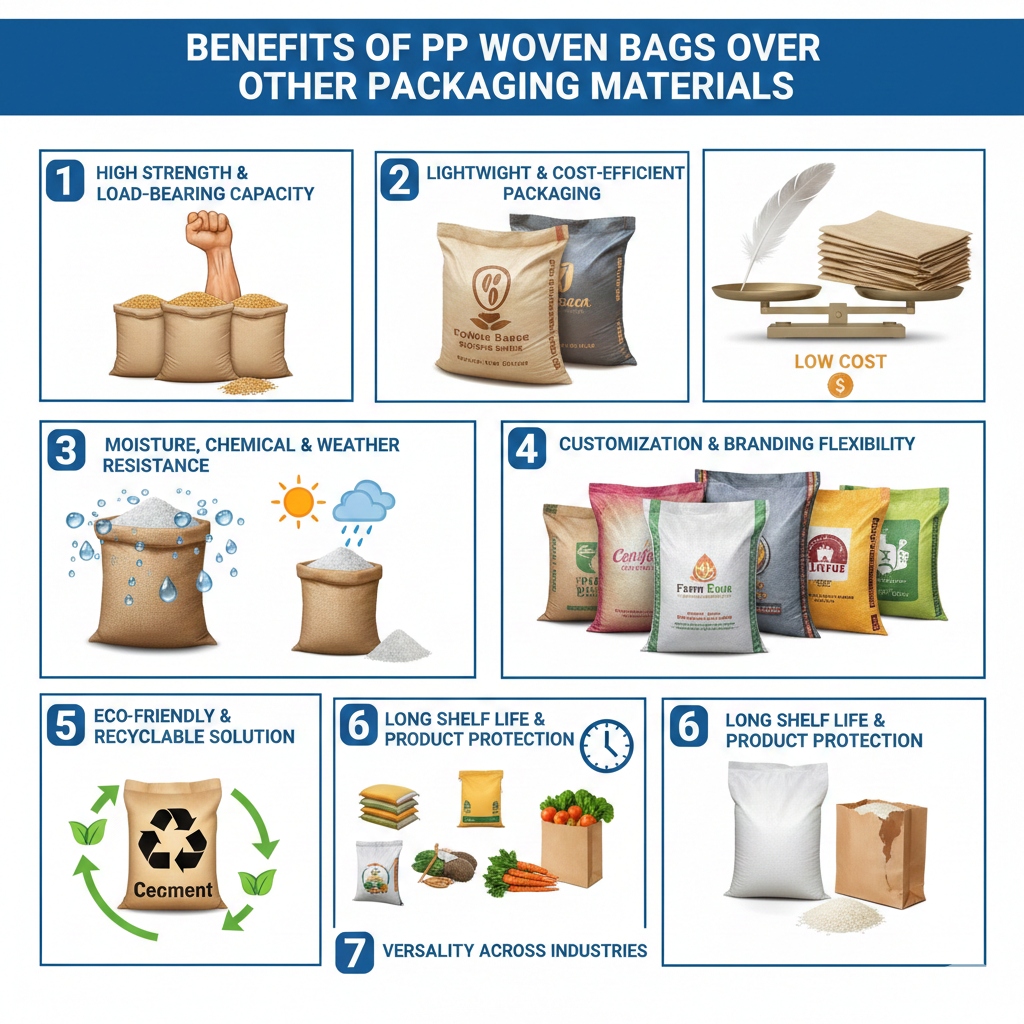

Benefits of PP Woven Bags Over Other Packaging Materials

When choosing industrial or agricultural packaging, businesses compare multiple options such as paper bags, jute bags, plastic films, and woven solutions. PP woven bags and sacks consistently stand out due to their strength, versatility, cost efficiency, and sustainability. As a professional PP woven fabric and bags manufacturer, we design PP woven packaging that outperforms traditional alternatives across key parameters.

Below are the major benefits of PP woven bags and why they are widely preferred across industries.

1 High Strength & Load-Bearing Capacity

PP woven bags are engineered to handle heavy loads without tearing or bursting.

Key Advantages

- High tensile and tear strength

- Excellent resistance to puncture

- Suitable for rough handling and stacking

Compared to paper or jute bags, PP woven sacks maintain structural integrity even under extreme conditions.

2 Lightweight & Cost-Efficient Packaging

Despite their strength, PP woven bags are lightweight, reducing logistics costs.

Cost Benefits

- Lower transportation costs

- Reduced packaging material usage

- Long service life and reusability

This makes PP woven bags a highly economical choice for bulk packaging.

3 Moisture, Chemical & Weather Resistance

PP woven fabric naturally resists moisture and many chemicals.

Protection Benefits

- Optional lamination for water resistance

- Chemical-resistant material structure

- UV stabilization for outdoor storage

This advantage is critical for cement, fertilizers, chemicals, and agricultural products.

4 Customization & Branding Flexibility

PP woven bags offer unmatched customization options.

Customization Features

- Custom sizes, GSM, and colors

- Multi-color printing and branding

- Gussets, liners, handles, and valves

Businesses can create branded PP woven sack bags that improve product visibility and market recognition.

5 Eco-Friendly & Recyclable Solution

Polypropylene is 100% recyclable, making PP woven bags an environmentally responsible packaging choice.

Sustainability Benefits

- Reusable for multiple cycles

- Lower carbon footprint compared to single-use packaging

- Supports circular economy initiatives

PP woven packaging aligns well with modern sustainable packaging goals.

6 Long Shelf Life & Product Protection

PP woven bags protect contents during storage and transportation.

Shelf-Life Advantages

- Resistance to humidity and pests

- Stable shape over long storage periods

- Reduced product wastage

This ensures consistent product quality across the supply chain.

7 Versatility Across Industries

One of the biggest benefits of PP woven packaging is its adaptability.

Industries Served

- Agriculture

- Cement & construction

- Food & beverages

- Chemicals & fertilizers

- Industrial and bulk logistics

From PP woven sack bags to PP woven big bags, one material serves multiple needs.

8 Comparison: PP Woven Bags vs Other Packaging Materials

| Feature | PP Woven Bags | Paper Bags | Jute Bags | Plastic Films |

|---|---|---|---|---|

| Strength | High | Low | Medium | Low |

| Moisture Resistance | High | Low | Medium | High |

| Reusability | High | Low | Medium | Low |

| Cost Efficiency | High | Medium | Low | Medium |

| Custom Printing | Excellent | Limited | Limited | Limited |

| Eco-Friendly | Recyclable | Biodegradable | Biodegradable | Non-recyclable |

How to Choose the Right PP Woven Fabric & Bags Manufacturer

Selecting the right PP woven fabric and bags manufacturer is crucial for ensuring product quality, supply consistency, and long-term cost efficiency. A reliable manufacturer does more than supply bags they become a packaging partner who understands your industry requirements and delivers consistent value.

Below are the key factors you should evaluate before finalizing a PP woven bag, sack, or big bag manufacturer.

1 Manufacturing Infrastructure & Capacity

A well-established manufacturer should have modern infrastructure and scalable production capacity.

What to Check

- In-house extrusion, weaving, lamination, printing, and stitching facilities

- Advanced circular and flat looms

- Ability to handle bulk and repeat orders

- Backup capacity to ensure uninterrupted supply

A strong infrastructure ensures consistent quality and timely delivery.

2 Quality Standards & Certifications

Quality assurance is non-negotiable when it comes to industrial and export packaging.

Key Quality Parameters

- Strict GSM and strength control

- Seam and stitching strength testing

- Load and drop testing (for big bags)

- Food-grade compliance (where required)

Manufacturers following structured quality systems deliver reliable PP woven sacks and bags every time.

3 Customization & Product Range

Every industry has unique packaging needs. A capable manufacturer should offer end-to-end customization.

Customization Capabilities

- Custom sizes and weight capacity

- GSM and fabric color options

- Lamination and coating choices

- Multi-color printing and branding

- Liners, gussets, handles, and valves

A wide product range indicates strong technical expertise.

4 Industry Experience & Application Knowledge

Experience matters in manufacturing PP woven packaging.

Why Experience Is Important

- Understanding of industry-specific requirements

- Ability to recommend suitable packaging solutions

- Reduced trial-and-error

- Better compliance with handling and storage needs

Manufacturers with multi-industry exposure deliver optimized packaging solutions.

5 Export Capability & Global Compliance

If you are sourcing packaging for export, compliance with international standards is essential.

Export-Readiness Checklist

- Consistent product quality for overseas shipments

- Proper packing and palletization

- UV-stabilized fabric for outdoor storage

- Safety factor compliance for PP woven big bags

An export-ready manufacturer ensures smooth international logistics.

6 Pricing Transparency & Cost Optimization

The lowest price does not always offer the best value.

What to Look For

- Transparent pricing structure

- Quality-to-cost balance

- Long-term cost savings through durable packaging

- Competitive pricing for bulk orders

A professional manufacturer focuses on value, not just price.

7 Reliable Delivery & After-Sales Support

Timely delivery and support are critical for uninterrupted operations.

Key Indicators

- Clear production timelines

- Reliable logistics partners

- Responsive customer support

- Ability to handle urgent requirements

Dependable service builds long-term partnerships.

8 Why Partnering with the Right Manufacturer Matters

Choosing the right PP woven fabric and bags manufacturer ensures:

- Consistent packaging quality

- Reduced product losses

- Improved brand image

- Smooth supply chain operations

Why Choose Us as Your PP Woven Fabric & Bags Manufacturer

As a reliable PP woven fabric and bags manufacturer, we combine advanced manufacturing technology, strict quality control, and customer-focused solutions to deliver high-performance PP woven packaging for domestic and international markets. Our goal is not just to supply bags, but to provide long-term packaging solutions that add value to your supply chain.

Here’s why businesses across industries choose us as their PP woven packaging partner:

1 Advanced Manufacturing Infrastructure

We operate a fully integrated manufacturing facility equipped with modern machinery.

Our infrastructure includes:

- High-capacity extrusion lines

- Circular and flat looms for precision weaving

- Lamination and coating units

- Advanced printing machines

- Dedicated stitching and finishing lines

This in-house production ensures consistent quality, better cost control, and faster turnaround times.

2 Wide Product Range Under One Roof

We manufacture a comprehensive range of PP woven products to serve multiple industries.

Our product portfolio includes:

- PP woven fabric rolls

- PP woven sacks and sack bags

- Laminated and BOPP laminated PP woven bags

- PP woven big bags (jumbo bags / FIBC)

- Custom-designed PP woven packaging

This allows customers to source all their PP woven packaging needs from a single trusted manufacturer.

3 Customization as per Industry Requirements

We understand that packaging requirements vary by industry and application.

Customization options offered:

- Custom dimensions, GSM, and fabric color

- Multi-color printing and branding

- Moisture-resistant lamination

- Liners, gussets, handles, and valves

- UV stabilization for outdoor use

Our customized solutions ensure optimal packaging performance for your products.

4 Strict Quality Control & Testing

Quality is at the core of our manufacturing process.

Our quality assurance includes:

- Raw material inspection

- GSM and tensile strength testing

- Stitching and seam strength checks

- Load and drop testing (for big bags)

- Final inspection before dispatch

This ensures that every PP woven sack, bag, and big bag meets high performance standards.

5 Export-Quality & Global Supply Capability

We are equipped to serve both domestic and international markets.

Export strengths include:

- Compliance with international packaging standards

- UV-stabilized and heavy-duty packaging options

- Secure packing and palletization

- Experience in handling export documentation

Our export-ready operations make us a preferred PP woven fabric and bags exporter.

6 Competitive Pricing & Reliable Supply

By managing the entire manufacturing process in-house, we offer:

- Competitive and transparent pricing

- Consistent product quality

- On-time delivery

- Reliable long-term supply partnerships

We focus on building mutually beneficial, long-term relationships with our clients.

7 Customer-Centric Approach

Our team works closely with clients to understand their packaging challenges and deliver solutions that meet their exact needs. From initial inquiry to post-delivery support, we ensure a smooth and professional experience.

Brand Spotlight: Oberon Polypack

Oberon Polypack is a well-known name in the PP woven packaging industry, recognized for manufacturing and exporting PP woven bags, BOPP laminated bags, and woven fabric solutions. With decades of experience, the brand serves multiple industries including agriculture, cement, food, chemicals, and bulk packaging.

The company is known for its consistent quality, wide product range, customization capabilities, and global export presence, making it a trusted benchmark brand in the polypropylene woven packaging market.

Conclusion

PP woven fabric and bags have become an essential packaging solution across industries due to their strength, durability, cost efficiency, and sustainability. From PP woven sacks and sack bags to PP woven big bags (jumbo bags), these packaging solutions offer reliable protection for storage, transportation, and export applications.

Choosing the right PP woven fabric and bags manufacturer ensures consistent quality, customization flexibility, and long-term value. With advanced manufacturing processes, strict quality control, and industry-focused solutions, PP woven packaging continues to be the preferred choice for agriculture, construction, food, chemical, and industrial sectors.

For businesses seeking dependable, high-performance packaging, PP woven bags remain a smart and future-ready solution.

Frequently Asked Questions (FAQs) – PP Woven Fabric & Bags

What is PP woven fabric?

PP woven fabric is a strong and lightweight material made by weaving flat polypropylene tapes in a crisscross pattern. It is widely used for manufacturing PP woven sacks, PP woven bags, sack bags, and PP woven big bags due to its high tensile strength, durability, and moisture resistance.

What are PP woven bags used for?

PP woven bags are used for packaging, storage, and transportation across multiple industries such as:

- Agriculture (grains, seeds, fertilizers)

- Cement and construction materials

- Food products (rice, flour, sugar)

- Chemicals and industrial raw materials

- Bulk export and logistics packaging

Are PP woven bags recyclable and eco-friendly?

Yes, PP woven bags are 100% recyclable and reusable. They offer a more sustainable packaging solution compared to single-use plastic packaging and support environmentally responsible packaging practices.

What is the difference between PP woven bags and PP non-woven bags?

PP woven bags are made by weaving polypropylene tapes, making them stronger and suitable for heavy-duty applications. PP non-woven bags are made from bonded fibers and are generally used for lightweight or promotional purposes.

What sizes and GSM are available in PP woven fabric and bags?

PP woven fabric and bags can be manufactured in a wide range of:

- GSM: 40 to 150+ GSM

- Sizes: Customized as per product weight and capacity

- Load capacity: From 5 kg small bags to 2000 kg jumbo bags

Customization depends on application requirements.

What is a PP woven big bag or jumbo bag?

A PP woven big bag, also known as a jumbo bag or FIBC, is a flexible intermediate bulk container designed to carry heavy loads ranging from 500 kg to 2000 kg. These bags are commonly used for bulk storage and transportation of industrial and agricultural materials.

Can PP woven bags be customized with printing and branding?

Yes, PP woven bags can be fully customized with:

- Multi-color printing

- Company logo and branding

- Product information and handling instructions

- BOPP lamination for premium appearance

Custom printed PP woven bags help improve brand visibility.

Are PP woven bags suitable for food packaging?

Yes, when manufactured using food-grade polypropylene and optional inner liners, PP woven bags are safe for packaging food products such as rice, flour, sugar, and grains.

How do I choose the right PP woven fabric and bags manufacturer?

You should consider:

- Manufacturing infrastructure

- Quality control processes

- Customization capabilities

- Industry experience

- Export readiness and compliance

- Pricing transparency and delivery reliability

Choosing the right manufacturer ensures consistent quality and long-term value.

Do you manufacture PP woven bags for export?

Yes, we manufacture export-quality PP woven sacks, bags, and big bags that meet international standards. Our products are designed for durability, safe handling, and long-distance transportation.

.png)