Introduction

The use of PP woven bags still remains a top solution to industrial and bulk packaging in 2026. They are tough, economical, and multipurpose and suitable in the fields of agriculture, construction, food and chemicals.

As the packaging needs are changing, it is necessary to know the types of PP woven bags and their use. Besides safeguarding products, the bags also aid in branding, sustainability and international export standards.

This guide discusses the uses of PP woven bags, its applications in the industry, and the current trends that can be used by a business to choose the appropriate packaging solution in terms of efficiency and safety in the long run.

What Are PP Woven Bags?

The PP woven bags are composed of polypropylene (PP) strips that have been woven to create a powerful and flexible fabric. This construction endows the bags with large tensile strength so that they are capable of holding heavy weights without being torn.

They are produced by extrusion, weaving, cutting and stitching, which are used to guarantee durability and uniform quality. The bags are portable, cheap and fit any industry, including agriculture and food, construction and chemicals.

PP woven bags are a good source of packaging since they are versatile, durable, and can be customized to be either small, medium, or large, as well as be printed and have protection.

- Plain PP Woven Bags

- Laminated PP Woven Bags

- BOPP Laminated PP Woven Bags

- Valve Type PP Woven Bags

- Gusseted PP Woven Bags

- Perforated PP Woven Bags

- PP Woven Bags with Liners

- UV Stabilized PP Woven Bags

Types of PP Woven Bags

The PP woven bags are of many different types that suit different packaging requirements. The selection of the appropriate type assures product safety, convenience in handling and efficiency in storage and transportation.

Each of the types is characterized by a distinct feature of being moisture resistant, ventilated, or more durable. The principal types of PP woven bags are plain, laminated, BOPP laminated, valve, gusseted, perforated, liner-fitted and UV stabilized bags.

In the following subsections, we’ll explore each type along with their common uses across industries.

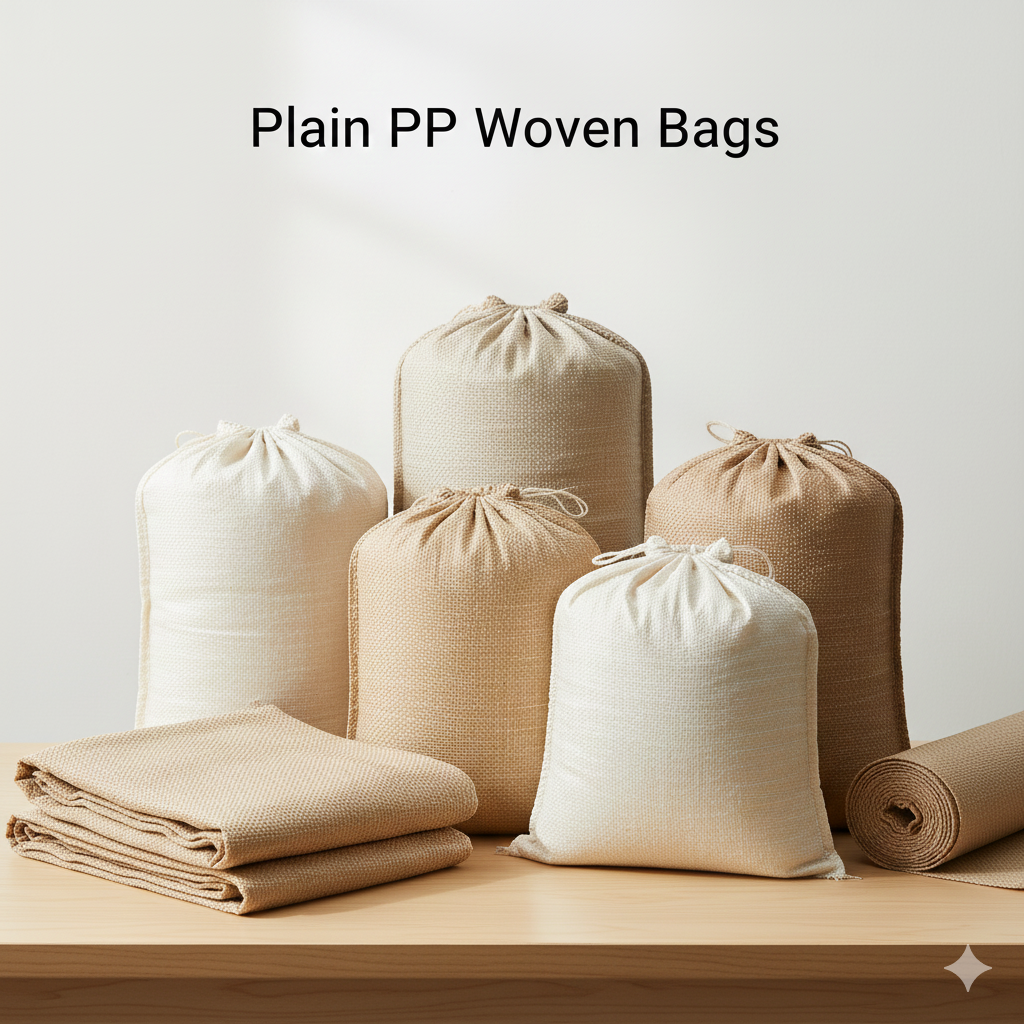

Plain PP Woven Bags

The most popular and the easiest type of woven bags are plain PP. They are made of woven polypropylene and are not laminated, hence are inexpensive but offer decent strength and durability.

These bags are the best options when dealing with heavy or bulk products, which do not need the protection of moisture or sophisticated branding. They are simple to use and can be used to package in large quantities.

Uses of Plain PP Woven Bags:

- Agriculture: grains, seeds, and pulses

- Construction: sand and cement

- General commodity storage and transport

Laminated PP Woven Bags

The woven bags made of Laminated PP are meant to offer an additional shield to moisture, dust and foreign contamination. On the inner surface or outer surface of the bag, a layer of lamination is added, which enhances the resistance and the barrier properties.

The bags assist in preserving product quality in the storage and transportation process particularly in damp conditions. It can also be printed and branded with ease with the smooth laminated surface.

Uses of Laminated PP Woven Bags:

- Fertilizers and chemicals

- Sugar and food grains

- Agricultural and industrial products

BOPP Laminated PP Woven Bags

BOPP woven bags with laminated PP are the high quality packaging materials that are strong in nature and rich in visual appeal. These bags have BOPP film lamination that has enabled sharp graphic, vivid colors and appealing branding.

BOPP lamination in addition to improved appearance has good resistance to moisture and surface protection. This renders the bags acceptable to products which need durability as well as high shelf presence.

Uses of BOPP Laminated PP Woven Bags:

- Pet food and animal feed

- FMCG and retail products

- Branded agricultural commodities

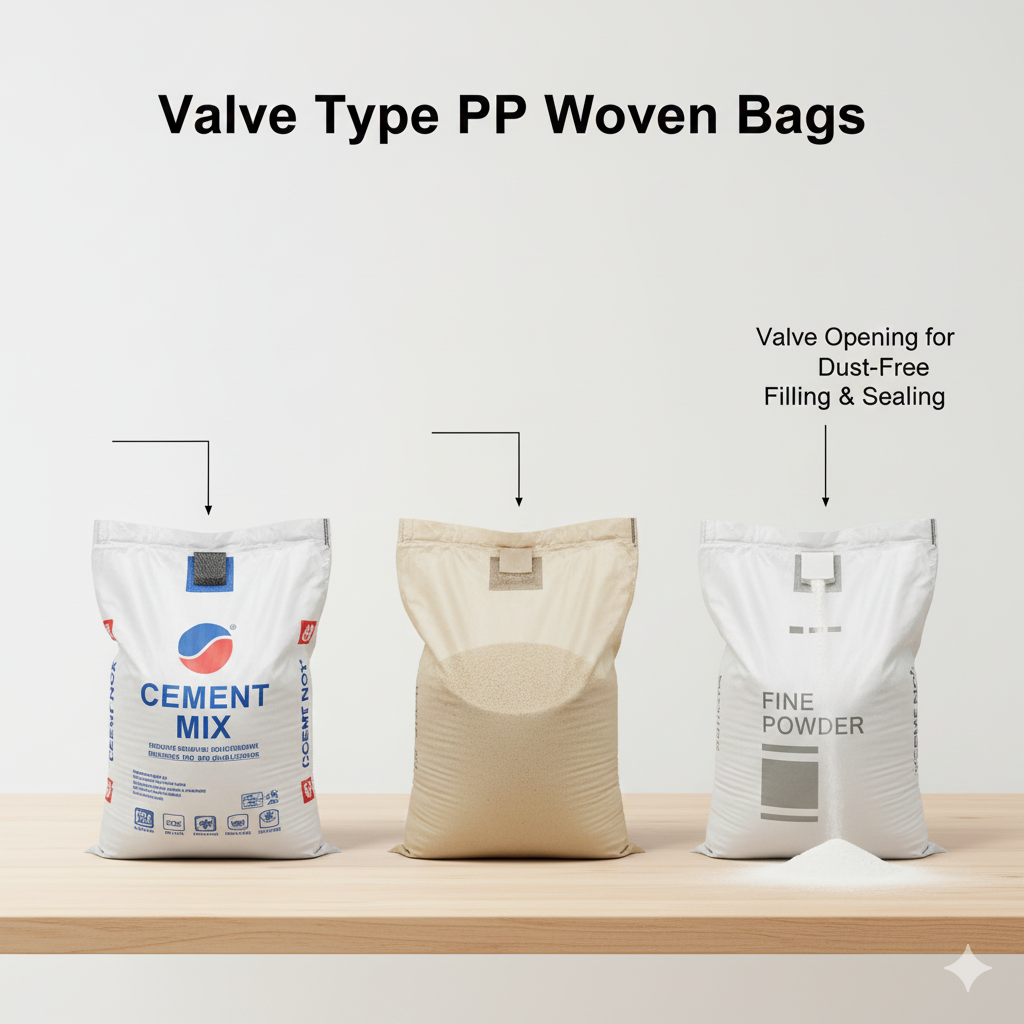

Valve Type PP Woven Bags

The PP woven bags with the valve type design are specifically engineered to be filled easily and without dust by using the automatic or semi-automatic fillers. They are characterized by the opening of a valve that can be filled controlled and minimized dust, spillage and loss of material.

The industries in which these bags are common are those where a high speed packaging and weight control is needed. They are highly structured and hence stable when handling and transportation.

Uses of Valve Type PP Woven Bags:

- Cement packaging

- Chemicals and mineral powders

- Construction materials

Gusseted PP Woven Bags

The gusseted PP woven bags have expandable side panels with an increased storage capacity and enhanced stability. These gussets enable the bag to stand in an upright position, hence, easy to stack and store.

The added structure also allows the weight to be perfectly distributed so that it does not tear during handling and transportation. Gusseted bags are perfect when it comes to products that should be packaged in a similar manner.

Uses of Gusseted PP Woven Bags:

- Rice and flour packaging

- Animal feed and pet food

- Bulk agricultural products

Perforated PP Woven Bags

The perforated PP woven bags have holes that are small enough to allow free circulation of air in the bag. This ventilation is useful in stopping the accumulation of moisture and ensures that products maintain their freshness when in storage and transportation.

Such bags are normally applied to the agricultural produce where breathability of the bags is of critical importance. The holes are well positioned such that they do not lower the overall strength of the bag.

Uses of Perforated PP Woven Bags:

- Vegetables and fruits

- Onions and potatoes

- Other perishable agricultural products

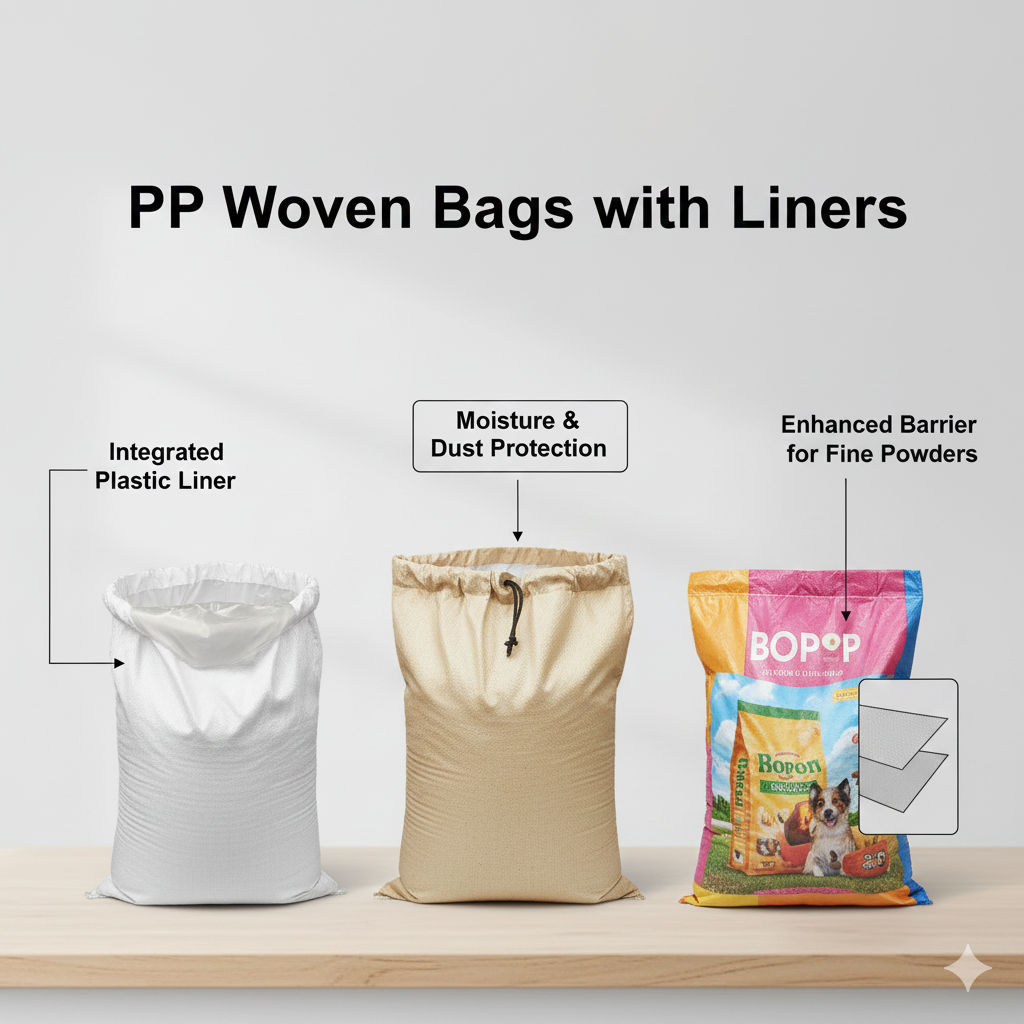

PP Woven Bags with Liners

The inner polyethylene liner ensures added protection against moisture, leakage, and contamination to PP woven bags with liners. This added feature will use them in sensitive and delicate materials.

The liner preserves the quality of the products, and the outer woven bag ensures the strength and durability in the process of handling and transportation. The bags are popular in areas where moisture and cleanliness are essential.

Uses of PP Woven Bags with Liners:

- Chemicals and fertilizers

- Food-grade products like sugar and grains

- Pharmaceutical and industrial raw materials

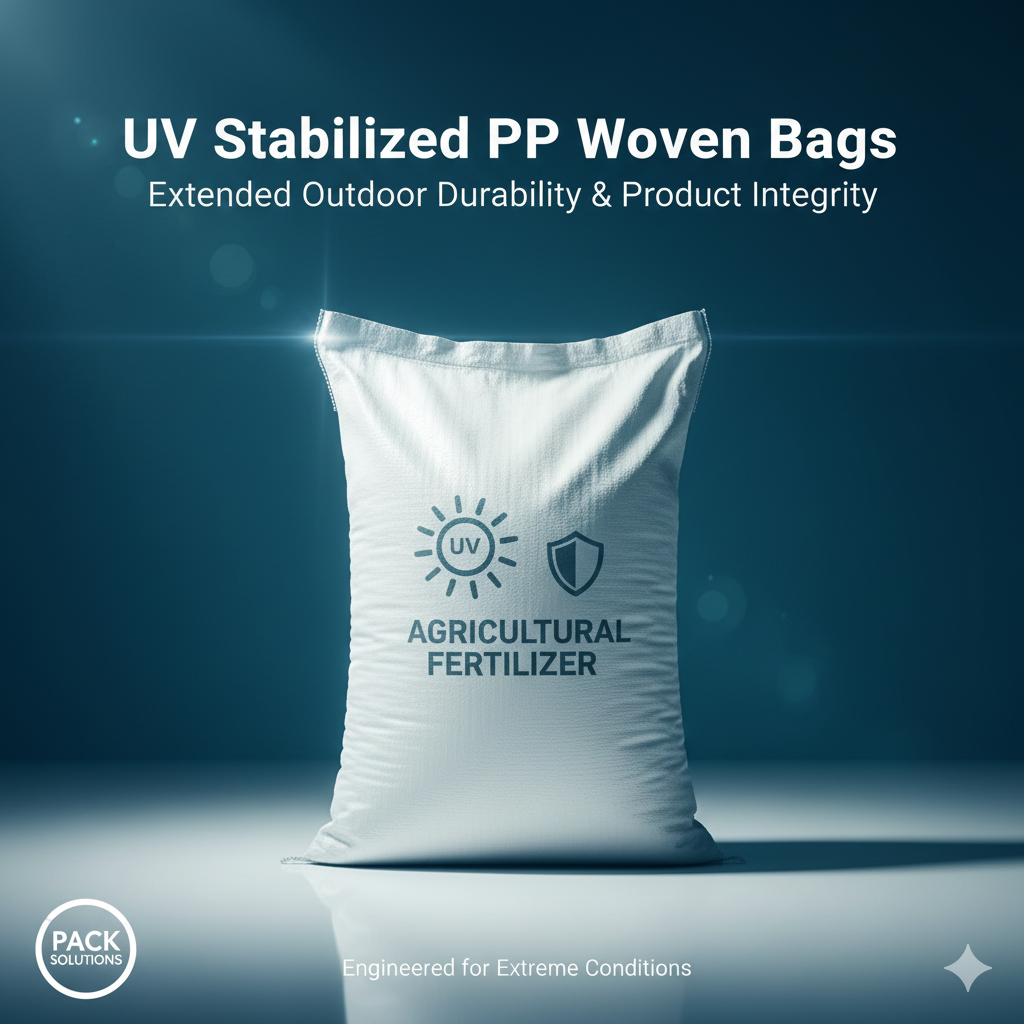

UV Stabilized PP Woven Bags

The UV stabilized PP woven bags are treated in a special way so that they do not get spoilt with the long duration of sunlight. This UV protection will avoid weakening, color deterioration, and brittle, so that it has a higher service life.

The bags can be used in the storage of products that have to be delivered long distances in the outdoors, where they are exposed to harsh weather. UV stabilization gives the bag strength even in extreme conditions.

Uses of UV Stabilized PP Woven Bags:

- Fertilizers and chemicals

- Cement and construction materials

- Agricultural exports and outdoor storage

PP Woven Bags Uses Across Industries

The application of PP Woven Bags Uses cuts across a number of industries because they are strong, flexible, and are capable of protecting products during storage and transportation. Their flexibility causes them to be among the most desired bulk packaging tools in the world.

PP woven bags have been popular in the agriculture sector as a packaging type of grains and seeds, pulses, fruits, and vegetables. Plain and perforated bags ensure that there is some air flow which keeps the bag fresh and avoids spoilage. They have high loading capacity hence suitable in transportation of huge agricultural quantities.

In the construction sector, cement, sand and other bulk materials are usually packed in PP woven bags. The UV stabilized bags of different types are made with care that they are safe to fill in, easy to handle and durable even when it is stored outside and when being transported over a long distance.

In case of the food and beverage industry hygiene and moisture protection is vital. Sugar, flour and rice among other dry food products are packaged using laminated and liner-fitted PP woven bags. These bags aid in preserving the quality of products and they are food-grade bags.

The chemical powders, granules and fertilizers are packed in PP woven bags in the chemicals and fertilizers industry. Laminated, lining, and UV stabilized versions will ensure a safe storage and handling of contents by shielding against moisture and contamination.

The retail and FMCG market depends on the BOPP laminated PP woven bag on branded products. These bags are well-printed, beautifully designed, and well positioned in the shelves without compromising on the durability and product safety.

In general, the diversity of the PP Woven Bags Uses in the various industries underscores their significance as a user-friendly, economical, and flexible packaging materials to the contemporary company.

Latest Trends in PP Woven Bags (2026)

The woven packaging sector of PP is developing fast in order to support the current requirement of efficiency, sustainability, and labeling. In 2026, the innovation is aimed at the better performance and fewer environmental effects.

Advanced printing and branding is one of the trends. The use of flexographic and rotogravure printing has given high-definition graphics and colors to BOPP laminated PP woven bags with vibrant colors. This assists brands to be isolated on the retail shelves and at the same time, retains good packaging integrity.

The change to lightweight but high-strength bags is another major trend. Manufacturers are also maximizing on GSM and fabric construction to minimize the use of materials without affecting the load bearing capacity. This reduces transport expenses and sustainable packaging activities.

There is also the increase in customization and design of applications. These are the customized products these businesses would prefer like valve bags used in cement and perforated bags in vegetables and liner-fitted bags in moisture-sensitive products. Individual sizes, types of stitching, and fasteners enhance efficiency in handling.

The issue of sustainability remains a factor in packaging. Reusable and recyclable woven PP bags, eco-friendly coating, and minimized plastic usage are all in line with the world environmental standards and requirements.

Finally, export ready PP woven bags are in high demand. International quality, safety, and compliance bags are gaining popularity in the world market as they guarantee safe transportation and durability.

Such trends indicate the way in which PP woven bags are adjusting to the evolving demands of industries in 2026 without compromising reliability, performance and sustainability of the products.

Advantages of PP Woven Bags Over Other Packaging Materials

PP woven bags have a number of benefits over the common packaging materials, including jute, paper, and HDPE bags. They have high levels of strength and flexibility which enable them to handle heavy loads without tearing and thus they are best suited to be used in bulk packaging.

The moisture resistance of PP woven bags is one of their main advantages. BOPP-coated and laminated with a liner is used to ensure goods against humidity and contaminants, a weakness of the paper and jute packaging.

PP woven bags are also light and inexpensive, which decreases the cost of transportation and storage. They do not accumulate moisture, unlike jute bags, and last much longer than the paper bags.

Customization and branding is another big benefit. Product information, logos and product designs may be printed on PP woven bags particularly, in BOPP laminated printing, to increase brand recognition in the retail and export markets.

Lastly, PP woven bags are re-usable and recyclable, which helps in sustainable packaging. They are an intelligent substitute of single-use packaging materials, due to their durability and environmental advantage.

How to Choose the Right PP Woven Bag

To make sure that products are safe, cost-effective, and have an efficient logistic process, it is necessary to select the appropriate PP woven bag. This is based on the type of the product, conditions of handling, and storage needs.

Begin by taking the product type and weight. Strong materials such as cement and minerals need strong alternatives, such as valve or gusseted PP woven bags, whereas agricultural goods which are not heavy might use plain or perforated bags.

Secondly, assess storage and transportation. UV stabilized and laminated bags are better protection against sunlight and moisture in an outdoor storage or a long-distance shipment.

Another factor is moisture sensitivity. Laminated PP woven bags with or without liner should be used to pack products like food items and chemicals, and fertilizers to avoid contamination and spoilage.

BOPP laminated PP woven bags have good printing and good looks which is why it is best suited to the retail and export market as fashionable companies are concentrated on branding their products.

The evaluation of these points will also help the businesses to choose the most appropriate PP woven bag that will guarantee durability, safety, and long-term value.

Why Choose Oberon Polypack for PP Woven Bags

Oberon Polypack is a reputable producer of high-grade PP woven bags, which provide different industries with high-quality packaging solutions. The company has good manufacturing knowledge and it is selling several types of PP woven bags that are intended to address various industrial needs.

Oberon Polypack has quality as one of its priorities. High quality control and production of the bags with high quality polypropylene material are used to make sure that the bags are durable, consistent and in performance.

Other customs that the company offers include size, GSM, color, and printing. This assists companies to design packages that secure products besides increasing brand recognition. Oberon Polypack is a stable partner in packaging with reliable supply and customer service oriented.

Conclusion

The strength, flexibility and low prices of the PP woven bags have made them an essential packaging solution used in industries. As there are many types of options to choose, different types of PP woven bags can be chosen by the business depending on the requirements of their product and handling.

The uses of the PP woven bags will continue to grow in 2026, as far as agriculture and construction as well as food, chemicals, and retail are concerned. Designed bags like laminated, BOPP, valves as well as UV stabilized are designed to provide enhanced protection, branding, and increase in service life.

In making a wise choice of packaging, businesses are able to know applications of industries, latest tendencies, and their selection criteria. Selecting an appropriate PP woven bag can be helpful in preserving the products besides ensuring sustainability, efficiency, and the expansion of the business in the long term.

Frequently Asked Questions (People Also Ask Section)

1. What are PP woven bags used for?

PP woven bags are used for packing and transporting bulk products such as grains, cement, fertilizers, chemicals, sugar, flour, and retail goods. Their strength and flexibility make them suitable for multiple industries.

2. What are the main types of PP woven bags?

The main types include plain PP woven bags, laminated bags, BOPP laminated bags, valve type bags, gusseted bags, perforated bags, liner-fitted bags, and UV stabilized PP woven bags.

3. Are PP woven bags suitable for food packaging?

Yes, PP woven bags are suitable for food packaging when they are laminated or fitted with inner liners. These options help maintain hygiene and protect food products from moisture and contamination.

4. Which PP woven bag is best for cement packaging?

Valve type PP woven bags and UV stabilized bags are best for cement packaging. They allow easy filling, reduce spillage, and withstand outdoor storage conditions.

5. Are PP woven bags eco-friendly?

PP woven bags are reusable and recyclable, making them a more sustainable option compared to single-use packaging. Their long life span also helps reduce overall packaging waste.

6. Can PP woven bags be customized?

Yes, PP woven bags can be customized in size, GSM, color, printing, lamination, and stitching. BOPP laminated bags are especially popular for branding and retail presentation.

.png)